Titanium Jewelry Factory

Titanium steel jewelry processing factory KEKE jewelry focuses on OEM, ODM customization and production of stainless steel jewelry at home and abroad. KEKE jewelry titanium steel jewelry is made according to strict technological process. Now KEKE jewelry author will let you know about it.

The technological process of titanium steel jewelry processing factory KEKE jewelry is as follows:

1. Wire cutting:

Use molybdenum wires of different sizes (a kind of metal with high hardness), use a wire cutting machine to cut out the shape of the jewelry at a very slow speed, and then polish it by hand. The more complex and difficult styles, the The goods are slower.

2. Precision die casting:

First, carve out the sample with wax, then put it in a special plaster, dewax it, dissolve the raw material with a high temperature of 1500~2000 degrees, then pour it into a plaster mold, pressurize it, demould it, and then polish it by hand. Because die casting requires a dedicated plaster mold, the price varies.

3. Polished surface:

Polishing wax is applied to the high-speed rotating cotton cloth polishing wheel, and the titanium steel jewelry processing factory then touches the jewelry to the cloth wheel to make the surface bright and reflect light. Some customers have misunderstood that it is electroplated. In fact, it is not electroplated, because the inner and outer materials of steel jewelry are the same, and only need to be polished to have a mirror effect. There are plated goods, we have instructions.

4. Sand surface:

Use sandpaper tape to make the surface of the jewelry a matte effect (light does not reflect), so that the surface has a matte effect.

5. Sandblasting:

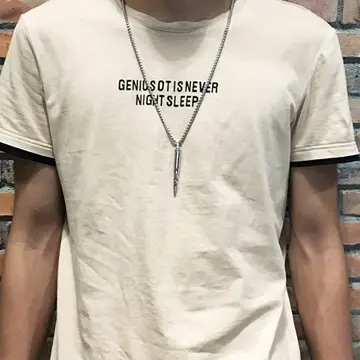

The main working principle of sandblasting is: the titanium steel jewelry processing factory places the sand (very fine abrasive, silver-gray) in water, and uses the grinding fluid pump and compressed air to spray the grinding fluid onto the surface of the steel jewelry at high speed through the spray gun to form a The layer of silver-gray coating makes the jewelry more elegant, and it is not easy to discolor, and it is more and more popular with people of all tastes. 6. Vacuum electroplating:

Vacuum plating mainly includes several types of ion plating, vacuum evaporation, sputtering and ion plating (also called nano-electroplating method), which are all deposited on the surface of objects by distillation or sputtering under vacuum conditions. Various metal and non-metal films can obtain very thin surface coatings in this way, and have the outstanding advantages of fast production speed and not easy to fade, but the price is also high, and there are fewer types of metals that can be operated. Functional coatings for jewelry and watches

7. Inlaid resin:

(Also called: Epoxy, hard plastic) First, the titanium steel jewelry processing factory heats the jewelry with high temperature, and then applies the resin to the jewelry. Because it is heat treated, it is not easy to fall off during the wearing process.

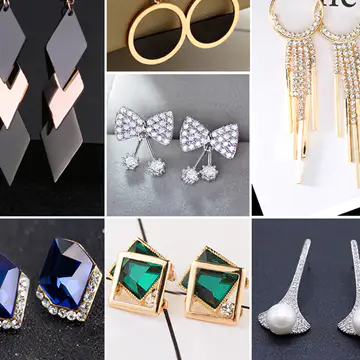

8. Inlaid with zircon:

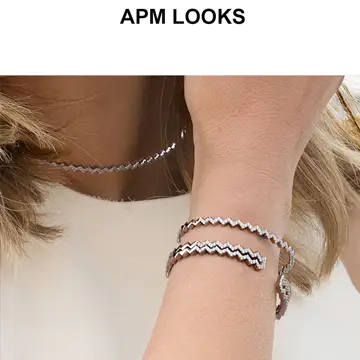

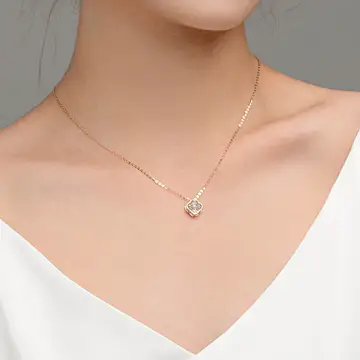

There are two main types. One is glued with AB glue. Because it is a special glue, it is very firm. The other is that the machine is pressed and inlaid, the workmanship is complex, very firm, and the workmanship is fine, but the price is more expensive than that with AB glue.

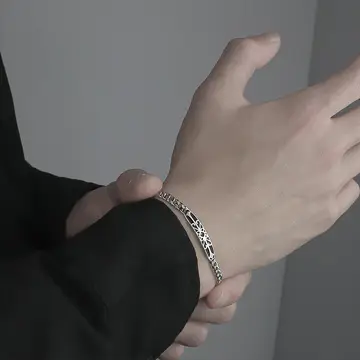

9. Inlaid carbon fiber:

It is expensive, but when used in jewelry, it has a three-dimensional effect with the movement of the line of sight, which is very beautiful. Carbon fiber is a fibrous carbon material that is used in some.

This article is from the stainless steel ring jewelry factory, Foshan Changan KEKE hardware jewelry processing factory. Please indicate the source for editing and reprinting of the article! Jewelry Processing Factory Foshan Changan KEKE Hardware Jewelry Processing Factory focuses on jewelry OEM, titanium steel jewelry processing, stainless steel jewelry processing, stainless steel bracelets, bracelets, bracelets, pendants, earrings, titanium steel necklace customization, titanium steel ring customization, titanium steel bracelet Manufacturers specializing in the production and processing of custom, jewelry custom processing and other products, welcome your consultation.

For the study, researchers defined Keke Jewelry as strategies to foster some social good, including programs that benefit community engagement, diversity, the environment, human rights and employee relations.

Dedicated to bringing you professional jewelry companies solutions and related products – from best jewelry manufacturers to custom jewelry manufacturers, Foshan KeKe Jewelry Co., Ltd. is your jewelry companies helper. Visit us at KeKe Jewelry.

It's the consistent experience that builds trust and loyalty. Creating a personality and platform that is scalable will allow you to evolve jewelry companies with your consumers.

Foshan KeKe Jewelry Co., Ltd. is an online resource for today's modern woman to live a green, healthy, and happy life. We offer jewelry companies, best jewelry manufacturers and more! Pls visit our site at KeKe Jewelry to know more.

Foshan KeKe Jewelry Co., Ltd. knows how important it is to offer optional extras, such as jewelry companiescustom jewelry manufacturers to provide quality products for customers.